A fagen sarrafa robobi, masu fitar da kaya suna taka muhimmiyar rawa wajen tsarawa da kuma mayar da polymers zuwa kayayyaki daban-daban. Daga cikin nau'o'in extruder iri-iri, conical twin screw extruders (CTSEs) da guda dunƙule extruders (SSEs) sun tsaya a matsayin fitattun zaɓi. Duk da yake nau'ikan biyu suna aiki da maƙasudin gama gari na sarrafa polymer, suna nuna halaye daban-daban da damar da suka sa su dace da aikace-aikace daban-daban. Wannan cikakken jagorar yana zurfafa cikin duniyar CTSEs da SSEs, yana bincika abubuwan musamman, fa'idodi, da aikace-aikacen da suka yi fice.

Conical Twin Screw Extruders: A Symphony of Mixing and Efficiency

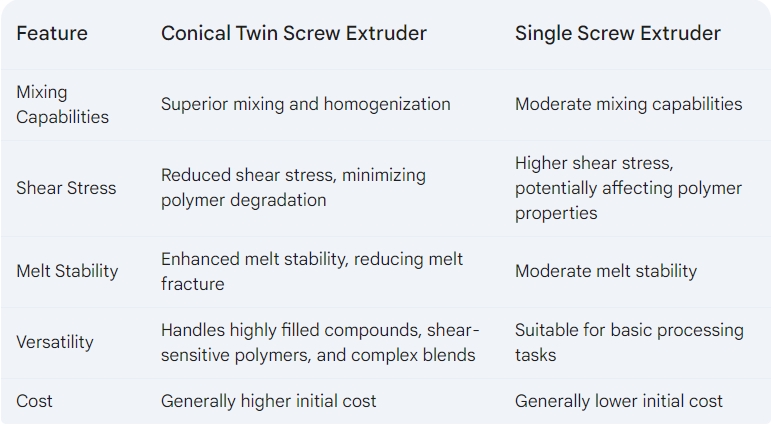

Conical twin screw extruders (CTSEs) sun shahara saboda iyawarsu ta musamman da kuma iyawa wajen sarrafa aikace-aikacen da ake buƙata. Siffar ma'anar su ita ce ƙirar ganga mai ɗanɗano, inda diamita na ganga a hankali ya ragu zuwa ƙarshen fitarwa. Wannan nau'in lissafi na musamman yana haɓaka haɗuwa mai ƙarfi da haɗin kai na gaurayawar polymer, ƙari, da filler, yana tabbatar da daidaitaccen rarraba kayan cikin narke.

Amfanin Conical Twin Screw Extruders:

Haɓaka Haɓakawa da Haɗuwa: CTSEs sun yi fice wajen samar da samfuran inganci tare da daidaiton kaddarorin da aiki, yana mai da su manufa don aikace-aikacen da ke buƙatar haɓakar haɓaka.

Rage Damuwar Shear: Ƙirar ƙira tana rage girman damuwa akan narke polymer, yana hana lalata polymer da tabbatar da ingancin samfur, musamman ga polymers masu ƙarfi.

Ingantacciyar Narkewar Narke: CTSEs suna haɓaka kwanciyar hankali narke, rage haɗarin narkewar karaya da tabbatar da santsi, daidaitaccen tsari na extrusion, mahimmanci don samar da samfuran tare da girma iri ɗaya da kaddarorin saman.

Yawanci don Aikace-aikacen Buƙatun: CTSEs suna ɗaukar mahadi masu cika sosai, polymers masu ƙarfi, da hadaddun polymers, yana mai da su dacewa da buƙatun aikace-aikace kamar waya da rufin kebul, robobin likitanci, robobin mota, marufi, da haɗawa/masterbatching.

Single Screw Extruders: Sauƙi da Tsari-Tasiri

Single dunƙule extruders (SSEs) wakiltar aikin doki na masana'antar sarrafa robobi, yana ba da mafita mai sauƙi da tsada don aikace-aikacen da yawa. Ƙirarsu ta ƙunshi dunƙule guda ɗaya da ke juyawa a cikin ganga silinda, isarwa, narkewa, da siffata polymer.

Amfanin Single Screw Extruders:

Zane mai sauƙi da Aiki: SSEs suna ba da tsari mai sauƙi da aiki, yana sa su sauƙi don kiyayewa kuma ba su da sauƙi ga lalacewa.

Tasirin Kuɗi: SSE gabaɗaya sun fi CTSEs araha, musamman don aikace-aikace inda hadaddun hadawa ko sarrafa kayan ƙalubale ba a buƙata.

Ya dace da Tsarin Gudanarwa: SSEs sun yi fice a ainihin ayyukan sarrafa polymer kamar pelletizing, haɗawa, da samar da bayanan martaba masu sauƙi, yana sa su dace da aikace-aikace masu tsada.

Zaɓan Madaidaicin Extruder: Al'amarin Aikace-aikace da Bukatu

Shawarar da ke tsakanin ƙwanƙwasa tagwayen maɗaukakiyar juzu'i (CTSE) da mai fitar da dunƙule guda ɗaya (SSE) ta dogara ne akan takamaiman aikace-aikacen da buƙatun sarrafawa. Don aikace-aikacen da ke buƙatar haɗakarwa mafi girma, rage damuwa mai ƙarfi, ingantacciyar kwanciyar hankali, da ikon sarrafa kayan ƙalubale, CTSEs sune zaɓin da aka fi so. Koyaya, don ayyukan sarrafawa na asali da aikace-aikace masu tsada, SSEs suna ba da mafita mai dacewa da tattalin arziki.

Kammalawa: Kewayawa Tsarin Kasa na Extruder

Zaɓin da ke tsakanin ƙwanƙwasa tagwaye mai jujjuyawar juzu'i (CTSE) da mai fitar da dunƙule guda ɗaya (SSE) ba yanke shawara ce mai girman-daya-daidai ba. A hankali kimanta takamaiman aikace-aikacen, buƙatun sarrafawa, da ƙuntatawa na kasafin kuɗi don tantance mafi dacewa nau'in extruder. Don aikace-aikacen da ake buƙata inda mafi kyawun hadawa, ingancin samfur, da ikon sarrafa kayan ƙalubale suke da mahimmanci, CTSEs suna fitowa a matsayin zaɓin zaɓi. Koyaya, don ayyukan sarrafawa na asali da aikace-aikace masu tsada, SSEs suna ba da mafita mai amfani da tattalin arziki. Ta hanyar fahimtar ƙarfi da iyakoki na kowane nau'in extruder, na'urori masu sarrafawa na iya yanke shawarar yanke shawara waɗanda ke inganta ayyukansu da cimma ingancin samfurin da ake so.

Lokacin aikawa: Juni-27-2024